The Role of Engineering in Custom Industrial Designs

- Jun 23, 2025

- 4 min read

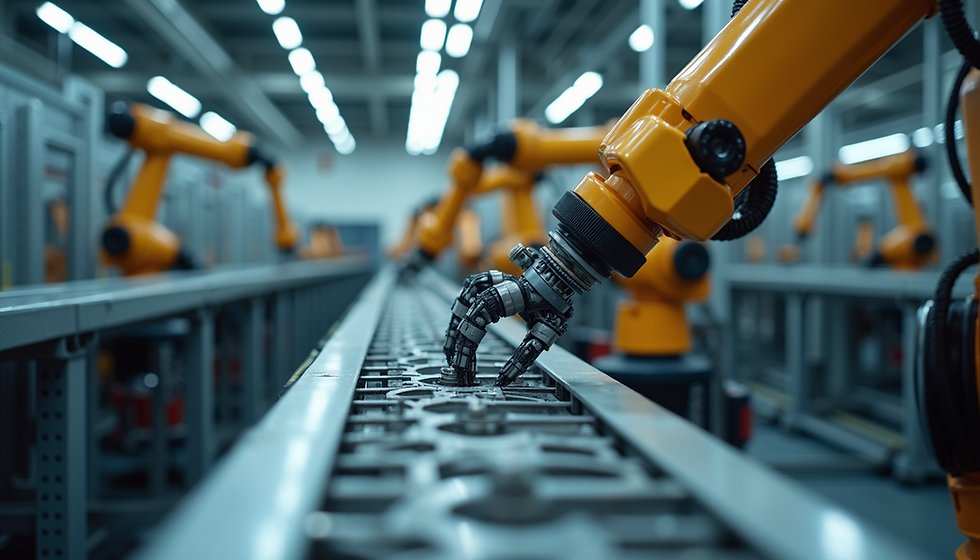

In the world of manufacturing and industrial development, engineering plays a vital role in creating custom designs that meet specific needs. From unique machinery to tailored production lines, engineers bring ideas to life, ensuring that each design is not only functional but also efficient and cost-effective. This blog post explores the role of engineering in custom industrial designs, its implications, and how it drives innovation.

Custom Engineering: The Heart of Industrial Design

Custom engineering involves the application of engineering principles to create products and systems tailored to specific requirements. This is particularly important in industries where standard solutions do not suffice. For instance, the manufacturing sector often requires specially designed machines to cater to unique production processes.

Engineers utilize a variety of tools and methodologies to create these custom designs, enhancing efficiency and meeting industry standards. They start by gathering information to understand the unique needs of the project. They analyze materials, design specifications, and operational requirements, allowing them to draft initial concepts that align with client expectations.

Custom engineering combines creativity with technical expertise. Engineers design everything from specialized packaging solutions to automated production systems, ensuring that every component works seamlessly together.

Another area where custom engineering shines is in the design of control panels. Personalized control systems are crucial for automating processes in factories. Custom engineers draw upon their knowledge of electrical engineering, systems design, and user interface to create intuitive control panels. This makes it easier for operators to monitor and manage workflows efficiently. For those seeking expertise in this area, precision engineering services can offer tailored solutions that meet the specific demands of modern industries.

Importance of Custom Designs in Engineering

Custom designs are essential for several reasons. First and foremost, they maximize efficiency. In industries where time is money, having equipment that works optimally can significantly reduce production costs. For example, a custom conveyance system can streamline material handling, ensuring that items are transported precisely where they are needed.

Additionally, custom designs often enhance the safety of operations. Engineering solutions can be tailored to comply with safety standards and regulations, minimizing the risks associated with industrial operations. A well-designed custom machine can incorporate safety features such as emergency stops and barriers that standard machines may lack.

Moreover, the scalability of custom designs cannot be understated. Businesses evolve, and their needs change over time. Custom-engineered solutions can be adapted and upgraded more easily compared to off-the-shelf products, enabling companies to remain competitive in a rapidly changing market.

Is Precision Engineering Profitable?

Investing in precision engineering can be highly profitable for businesses. First, consider the tools and machinery developed through precision engineering—these often yield better performance and longevity. This means less downtime and lower maintenance costs over the long term.

Furthermore, customized solutions allow companies to differentiate themselves in crowded markets. Businesses that provide unique products or services can command higher prices, leading to increased revenues. For instance, a manufacturer of specialized automotive components could see higher profit margins by delivering custom designs that meet the exact specifications of client vehicles.

Another profitability aspect is the reduction in waste that comes from improved manufacturing processes. Precision engineering minimizes errors and inefficiencies, ensuring that materials are utilized effectively. In fact, studies have shown that businesses employing advanced custom engineering solutions can reduce production waste by up to 30 percent.

Challenges in Custom Industrial Designs

Despite the advantages, custom industrial designs are not without their challenges. One primary concern is the cost. Developing a custom solution can require a significant upfront investment. Businesses must weigh this initial expense against the expected long-term benefits. Often, careful analysis is necessary to ensure that the investment is feasible and aligned with their operational goals.

Another challenge is the complexity of integrating custom designs into existing systems. Engineers must ensure that new designs can work in harmony with current operations. This may require additional testing and adjustments, slowing down the implementation process.

Furthermore, the rapid pace of technological advancement can pose a challenge. As new technologies emerge, engineers must continually update their skills and knowledge. This means investing in training and development to stay competitive in the field of custom engineering.

The Future of Custom Engineering in Industry

Looking ahead, the future of custom engineering in industry appears bright. Emerging technologies such as artificial intelligence and machine learning are expected to play a significant role in custom design. These technologies can aid engineers in creating smarter solutions that adapt to real-time data, making industrial processes more efficient than ever before.

Additionally, the increased focus on sustainability is driving demand for custom solutions that reduce environmental impact. Engineers are tasked with developing products and processes that minimize energy consumption and waste production, leading to greener manufacturing practices.

Furthermore, the advent of 3D printing technology has revolutionized custom engineering. This innovation allows for rapid prototyping and the creation of complex designs without the high costs typically associated with traditional manufacturing methods. As 3D printing technology continues to evolve, it will undoubtedly open new doors for custom industrial designs.

Final Thoughts on Custom Industrial Engineering

The role of engineering in custom industrial designs is multi-faceted and ever-evolving. From increasing efficiency and profitability to overcoming challenges and embracing new technologies, engineers are at the forefront of innovation in this field.

As businesses continue to seek ways to differentiate themselves in competitive markets, the importance of tailored engineering solutions will only grow. By investing in custom designs, companies can not only boost their bottom lines but also contribute to a more sustainable future in manufacturing.

For manufacturers looking to enhance their operations, focusing on custom engineering could be the key to unlocking their potential. Whether through developing unique machinery or optimizing production lines, the application of engineering principles in custom designs leads to success in a dynamic industrial landscape.

Comments