Choosing the Right Control Systems in the UK: A Control Systems Guide

- 1 day ago

- 4 min read

Selecting the appropriate control system is a critical decision for any business or industrial operation. The right control system can improve efficiency, reduce costs, and enhance safety. In the UK, where industries range from manufacturing to energy and infrastructure, understanding the options and requirements for control systems is essential. This guide will walk you through the key considerations, types of control systems, and practical advice to help you make an informed choice.

Understanding Control Systems: A Control Systems Guide

Control systems are frameworks that manage, command, direct, or regulate the behaviour of other devices or systems. They are essential in automating processes, ensuring consistency, and maintaining quality. In the UK, industries rely heavily on control systems to meet regulatory standards and optimise operations.

There are two main types of control systems:

Open-loop control systems: These operate without feedback. They perform actions based on preset instructions without adjusting for changes in the environment.

Closed-loop control systems: These use feedback to adjust their operations dynamically, improving accuracy and responsiveness.

For example, a heating system that adjusts temperature based on a thermostat reading is a closed-loop system. In contrast, a simple timer-based irrigation system that waters plants at fixed intervals without sensing soil moisture is an open-loop system.

Choosing between these depends on the complexity of your process and the level of control required.

Key Factors to Consider When Choosing Control Systems: A Control Systems Guide

When selecting a control system, several factors must be evaluated to ensure it fits your specific needs:

1. Application Requirements

Identify what the control system needs to manage. Is it a manufacturing line, HVAC system, or energy distribution? Each application demands different capabilities. For instance, a manufacturing plant may require a programmable logic controller (PLC) for precise automation, while a building management system (BMS) might focus on energy efficiency and environmental control.

2. Scalability and Flexibility

Your control system should accommodate future growth or changes. Modular systems allow you to add components or upgrade software without replacing the entire system. This flexibility is crucial in dynamic industries where processes evolve.

3. Integration with Existing Systems

Consider how the new control system will integrate with your current infrastructure. Compatibility with existing hardware and software reduces costs and downtime. Many modern control systems support standard communication protocols like Modbus, Profibus, or Ethernet/IP to facilitate integration.

4. Reliability and Maintenance

Choose systems known for reliability and ease of maintenance. Downtime can be costly, so systems with robust diagnostics and remote monitoring capabilities are advantageous. Additionally, consider the availability of local support and spare parts in the UK.

5. Compliance and Standards

Ensure the control system complies with UK and European standards, such as CE marking and ISO certifications. Compliance guarantees safety, quality, and legal adherence.

6. Cost Considerations

Balance initial investment with long-term operational costs. Sometimes, a higher upfront cost for a more efficient system results in savings over time through reduced energy consumption and maintenance.

Popular Types of Control Systems in the UK

Understanding the common types of control systems used in the UK can help you identify what suits your needs best.

Programmable Logic Controllers (PLCs)

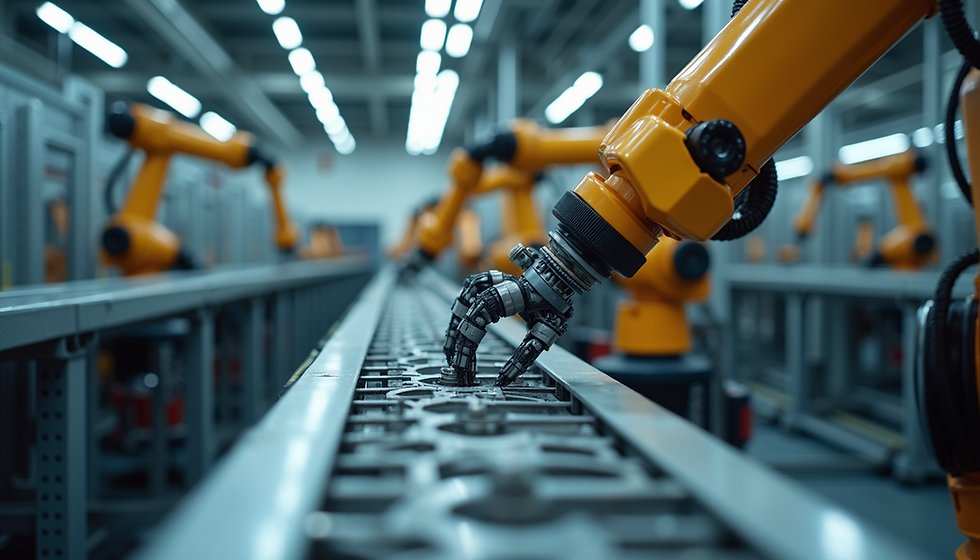

PLCs are widely used in industrial automation. They are rugged, reliable, and programmable to handle complex tasks. For example, a car manufacturing plant may use PLCs to control robotic arms and assembly lines.

Distributed Control Systems (DCS)

DCS are used for large-scale processes like chemical plants or power stations. They distribute control functions across multiple controllers, enhancing reliability and scalability.

Building Management Systems (BMS)

BMS control heating, ventilation, air conditioning, lighting, and security in commercial buildings. They improve energy efficiency and occupant comfort.

Supervisory Control and Data Acquisition (SCADA)

SCADA systems monitor and control infrastructure and industrial processes remotely. They are common in utilities like water treatment and electricity distribution.

Practical Steps to Implement Your Control System

Once you have selected the right control system, follow these steps to ensure successful implementation:

Define Clear Objectives

Set measurable goals such as reducing energy consumption by 10% or increasing production speed by 15%. Clear objectives guide system design and evaluation.

Engage Stakeholders

Involve operators, engineers, and management early in the process. Their input ensures the system meets practical needs and gains user acceptance.

Choose Experienced Suppliers

Work with reputable suppliers who understand the UK market and regulatory environment. They can provide tailored solutions and ongoing support.

Plan for Training

Ensure staff receive comprehensive training on the new system. Well-trained personnel reduce errors and improve system utilisation.

Test Thoroughly

Conduct rigorous testing before full deployment. Simulate different scenarios to verify system performance and safety.

Monitor and Maintain

After installation, continuously monitor system performance and schedule regular maintenance. Use data analytics to identify improvement opportunities.

Future Trends in Control Systems

The control systems landscape is evolving rapidly with technological advancements. Staying informed about trends can help future-proof your investment.

IoT Integration: Internet of Things (IoT) devices enable real-time data collection and remote control, enhancing system responsiveness.

Artificial Intelligence (AI): AI algorithms can optimise control strategies, predict failures, and automate decision-making.

Cybersecurity: As control systems become more connected, protecting them from cyber threats is paramount.

Sustainability Focus: Control systems increasingly support energy-saving initiatives and compliance with environmental regulations.

By considering these trends, you can select systems that not only meet current needs but also adapt to future challenges.

Making the Most of Control Systems in the UK

Choosing the right control system is a strategic decision that impacts operational efficiency, safety, and cost-effectiveness. Whether you are upgrading an existing system or installing a new one, thorough research and planning are essential.

For businesses operating in the UK, leveraging local expertise and resources can provide a competitive edge. Accessing control systems uk suppliers and consultants ensures compliance with regional standards and access to tailored solutions.

Investing time in understanding your specific requirements, evaluating options, and planning implementation will pay dividends in improved performance and reduced risks.

By following this guide, you can confidently navigate the complex landscape of control systems and select the best solution for your needs. The right control system is not just a tool but a foundation for operational excellence and innovation.

Comments