The Future of Industrial Automation: Embracing Change

- Nov 26, 2025

- 3 min read

Updated: Feb 4

The Role of Industrial Automation in Modern Manufacturing

Industrial automation refers to the use of control systems, such as computers or robots, and information technologies to handle different processes and machinery in an industry. The goal is to increase productivity, improve quality, and reduce human intervention in repetitive or hazardous tasks.

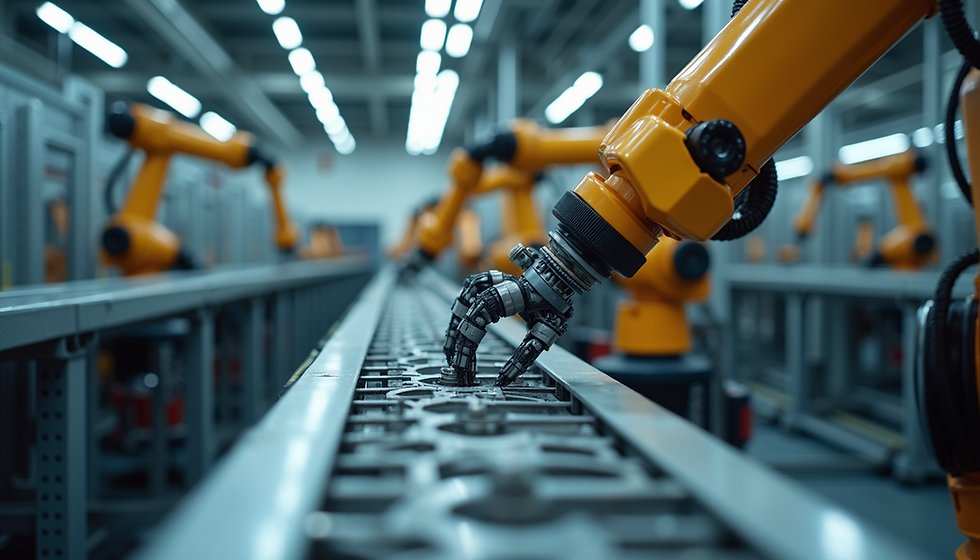

Today, automation is no longer limited to simple mechanical tasks. It encompasses complex systems that integrate sensors, data analytics, and artificial intelligence (AI) to create adaptive and intelligent manufacturing environments. For example, automotive factories use robotic arms for precise assembly, while food processing plants employ automated sorting and packaging lines to maintain hygiene and speed.

The benefits of industrial automation include:

Increased production speed: Machines operate faster and more consistently than humans.

Improved product quality: Automation reduces errors and variability.

Enhanced safety: Dangerous tasks are handled by machines, reducing workplace injuries.

Cost savings: Lower labour costs and less material waste.

Data-driven insights: Real-time monitoring enables proactive maintenance and optimisation.

Emerging Technologies Driving Industrial Automation

Several cutting-edge technologies are driving the next wave of industrial automation. These innovations are enabling smarter, more flexible, and more efficient production systems.

Artificial Intelligence and Machine Learning

AI algorithms analyse vast amounts of data from sensors and machines to detect patterns, predict failures, and optimise processes. Machine learning models can adapt to changing conditions, improving over time without human intervention. For instance, predictive maintenance uses AI to forecast equipment breakdowns before they happen, reducing downtime and repair costs.

Internet of Things (IoT)

IoT connects machines, sensors, and devices across the factory floor, creating a network of smart equipment. This connectivity allows for real-time data collection and remote monitoring. Factories can track inventory levels, machine performance, and environmental conditions instantly, enabling faster decision-making.

Robotics and Collaborative Robots (Cobots)

Robots have been a staple of automation for decades, but the rise of cobots is a game-changer. Cobots work alongside human operators safely, assisting with tasks that require precision or strength. They are easy to program and can be redeployed quickly, making them ideal for small batch production and customisation.

Advanced Control Systems

The integration of advanced control systems is crucial for managing complex automation processes. These systems provide precise control over machinery and processes, ensuring optimal performance and adaptability. They enable seamless coordination between different components of the production line, improving efficiency and reducing errors.

Practical Applications of Industrial Automation Technologies

The impact of these technologies is visible across various industries, each benefiting in unique ways.

Automotive Industry

Automation has revolutionised car manufacturing. Robots perform welding, painting, and assembly with high precision. AI-driven quality control systems inspect parts for defects, ensuring safety and reliability. IoT sensors monitor equipment health, preventing costly breakdowns.

Food and Beverage

Automation ensures consistent product quality and hygiene. Automated sorting systems use machine vision to detect and remove defective items. Packaging lines operate 24/7 with minimal human supervision, increasing throughput.

Pharmaceuticals

Precision and compliance are critical in pharmaceuticals. Automation controls dosing, mixing, and packaging processes to meet strict regulatory standards. Data logging and traceability are enhanced through connected systems.

Electronics Manufacturing

Small components require delicate handling. Cobots assist in assembly, while AI algorithms optimise production schedules. Real-time monitoring helps maintain cleanroom conditions and prevent contamination.

How Businesses Can Prepare for the Future of Industrial Automation

To leverage the benefits of industrial automation, businesses should take proactive steps:

Assess current processes: Identify repetitive, hazardous, or error-prone tasks suitable for automation.

Invest in training: Equip staff with skills to operate and maintain automated systems.

Adopt scalable solutions: Choose technologies that can grow with your business needs.

Focus on data integration: Ensure systems can communicate and share data seamlessly.

Partner with experts: Collaborate with technology providers who understand your industry challenges.

By embracing these strategies, companies can improve productivity, reduce costs, and stay competitive in a rapidly changing market.

The Road Ahead: Trends to Watch in Industrial Automation

Looking forward, several trends will continue to shape industrial automation:

Increased use of AI and analytics for deeper insights and autonomous decision-making.

Greater adoption of edge computing to process data locally and reduce latency.

Expansion of 5G networks enabling faster and more reliable machine communication.

Sustainability-focused automation to reduce energy consumption and waste.

Human-machine collaboration evolving with smarter cobots and augmented reality tools.

These developments will create more agile, efficient, and environmentally friendly manufacturing environments.

Industrial automation is no longer just about replacing manual labour. It is about creating intelligent systems that enhance human capabilities and drive innovation. By staying informed and adaptable, businesses can harness technology to build a resilient and prosperous future.

Comments