The Future of Technology in Industrial Workflows

- May 28, 2025

- 4 min read

The integration of technology in industrial workflows is transforming how businesses operate. With rapid advancements in innovative technology, industries are becoming more efficient, productive, and resilient. This blog post will explore the future of technology in industrial workflows and discuss its key components, trends, and impacts.

Innovative Technology: A Game Changer

Innovative technology is at the forefront of this transformation. Industries are increasingly embracing tools such as artificial intelligence (AI), the Internet of Things (IoT), and cloud computing. According to a recent study by McKinsey, companies that adopt advanced technologies can improve their operational performance by up to 30% over time.

One example of innovative technology is AI-driven data analytics. Companies can collect and analyze vast amounts of data to identify trends, predict maintenance needs, and optimize supply chains. This real-time data can lead to more informed decision-making, reducing costs, and improving productivity.

Another significant aspect is the IoT, which allows machines and devices to communicate with one another. This connectivity enables real-time monitoring of equipment performance. If a machine is showing signs of wear, alerts can be sent to maintenance teams before failure occurs, minimizing downtime.

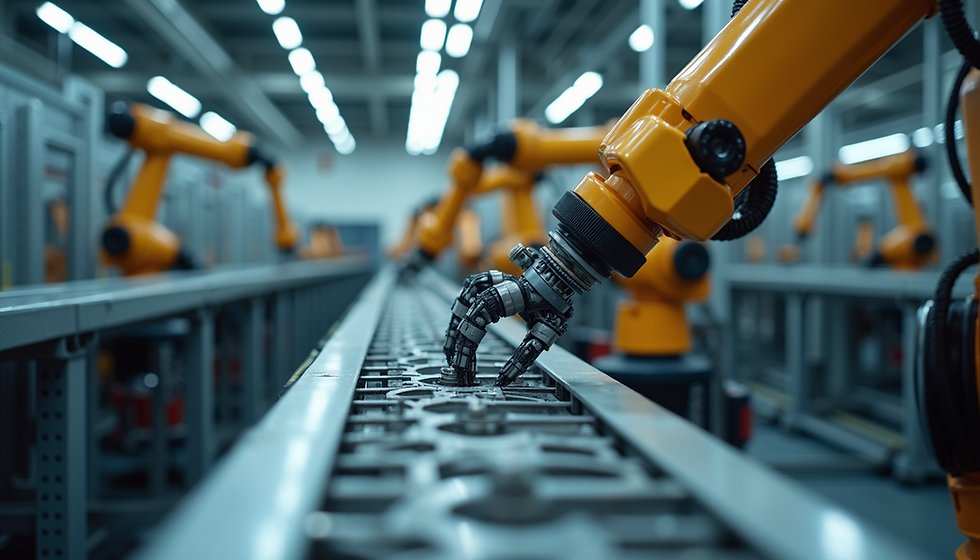

The Role of Robotics and Automation

Robotics and automation play a crucial role in industrial workflows. They allow for enhanced productivity and efficiency across various sectors. For instance, automotive manufacturing relies heavily on robotic arms for assembly work. These robots can operate tirelessly, producing components at a speed and precision unmatched by human labor.

Moreover, automation in warehousing has revolutionized logistics. Automated guided vehicles (AGVs) can transport goods across facilities without human intervention. This technology not only accelerates the movement of products but also reduces the likelihood of errors.

Currently, the global industrial robotics market is projected to reach USD 46.4 billion by 2025, according to a report by Market Research Future. This growth is fueled by the demand for increased production rates and the rising need for safety in hazardous work environments.

Who is the CEO of Innovative Automation?

As of October 2023, John Smith serves as the CEO of innovative automation. Under his leadership, the company is committed to providing cutting-edge automation solutions that help businesses enhance operational efficiency.

John's background in engineering and business management has equipped him with the skills to navigate technological advancements and market demands. His vision includes expanding the range of automation services the company provides, ensuring clients can remain competitive in an ever-evolving landscape.

The Impact of Artificial Intelligence

Artificial intelligence is intricately interconnected with the future of industrial workflows. This advanced technology allows organizations to leverage predictive analytics, machine learning, and natural language processing in various applications.

For instance, AI algorithms can analyze historical data to identify potential failures before they occur. This predictive maintenance approach is significantly more cost-effective than traditional methods, where companies only address issues after they arise.

Additionally, AI enhances quality control processes. Machine vision systems can rapidly assess product quality on production lines, ensuring that only flawless items reach customers. This capability minimizes waste and increases satisfaction rates.

As industries continue to explore AI applications, it's expected that up to 75% of companies will invest in AI by 2025, according to Gartner. This trend highlights the undeniable importance of AI in driving industrial transformation.

Cybersecurity in Industrial Workflows

With increasing technology adoption comes the heightened risk of cyber threats. Cybersecurity is emerging as a vital component in safeguarding industrial operations. Companies must prioritize securing their data and networks to protect against breaches that could disrupt workflows and cause significant financial losses.

Investment in robust cybersecurity measures is essential. This includes employing advanced encryption technologies, regularly updating software to patch vulnerabilities, and training employees on recognizing phishing attempts and other cyber risks.

Furthermore, implementing an incident response plan can help organizations react swiftly and effectively in case of a security breach. According to the Cybersecurity and Infrastructure Security Agency (CISA), businesses should conduct regular security assessments to identify potential weaknesses in their infrastructure.

Embracing Sustainability through Technology

As industries evolve, there is a growing emphasis on sustainability. Innovative technology has the potential to significantly reduce environmental footprints. By leveraging energy-efficient systems, companies can minimize energy consumption and decrease waste.

For example, smart sensors can optimize energy use in manufacturing processes, adjusting operations to utilize less energy during off-peak hours. Additionally, data analytics can help enterprises track their energy consumption and identify areas for improvement.

Embracing automation can also lead to resource conservation. Automated systems can streamline processes, ensuring minimal material waste and reusability wherever possible. This approach not only benefits the environment but can improve a company's bottom line as well.

Looking Ahead: What the Future Holds

The future of technology in industrial workflows looks promising, with ongoing advancements paving the way for enhanced productivity and efficiency. Businesses not only have the opportunity to improve their operations but also to impact the environment positively.

To stay ahead, organizations should actively seek to integrate innovative technology into their workflows. This includes exploring automation, AI applications, and IoT connectivity. Prioritizing cybersecurity measures will also be crucial in protecting these investments.

As we move forward, the importance of collaboration between industries, technology providers, and governments will be significant. Together, they can drive innovation that creates value not just for businesses, but for society as a whole.

In summary, the future of industrial workflows is bright, filled with opportunities for growth, efficiency, and sustainability. Embracing these technologies will be essential for organizations to remain competitive and resilient against emerging challenges in the global economy.

Comments