Steps to Streamline Industrial Operations

- Oct 7, 2025

- 3 min read

In today’s competitive industrial landscape, streamlining operations is essential for maintaining efficiency, reducing costs, and improving product quality. Industrial operations often involve complex workflows, multiple teams, and various machinery, making it crucial to adopt strategies that enhance productivity and minimise waste. One of the most effective ways to achieve this is through process optimization. This blog post explores practical steps to streamline industrial operations by leveraging process optimization techniques and tools.

Understanding Process Optimization in Industrial Operations

Process optimization involves analysing and improving existing workflows to make them more efficient and effective. It focuses on identifying bottlenecks, reducing downtime, and enhancing resource utilisation. In industrial settings, this can mean anything from automating repetitive tasks to redesigning production lines for better flow.

Key benefits of process optimization include:

Increased production speed without compromising quality

Lower operational costs through waste reduction

Enhanced flexibility to adapt to market changes

Improved safety and compliance with regulations

For example, a manufacturing plant might use data analytics to monitor machine performance and predict maintenance needs, preventing unexpected breakdowns that halt production.

How to Implement Process Optimization in Industrial Settings

Implementing process optimization requires a structured approach. Here are the essential steps to get started:

1. Map Current Processes

Begin by documenting all existing workflows in detail. Use flowcharts or process maps to visualise each step, from raw material intake to final product delivery. This helps identify redundant or inefficient activities.

2. Collect and Analyse Data

Gather data on production times, machine utilisation, defect rates, and other relevant metrics. Use this data to pinpoint bottlenecks or areas where resources are underused.

3. Set Clear Objectives

Define what you want to achieve with process optimization. Objectives could include reducing cycle time by 20%, cutting energy consumption, or improving product consistency.

4. Identify Improvement Opportunities

Based on your analysis, look for specific changes that can enhance efficiency. This might involve upgrading equipment, retraining staff, or introducing automation.

5. Test and Implement Changes

Pilot your proposed improvements on a small scale to assess their impact. Once validated, roll them out across the operation.

6. Monitor and Refine

Continuously track performance to ensure improvements are sustained. Use feedback loops to make further adjustments as needed.

By following these steps, industrial operations can become more agile and cost-effective.

What is the Role of Process Optimizer?

A process optimizer plays a critical role in streamlining industrial operations. This individual or team is responsible for analysing workflows, identifying inefficiencies, and implementing solutions that improve overall performance.

Responsibilities of a Process Optimizer:

Data Analysis: Collecting and interpreting operational data to find improvement areas.

Collaboration: Working with engineers, operators, and management to design better processes.

Technology Integration: Recommending and deploying automation tools or software that enhance productivity.

Training: Educating staff on new procedures and best practices.

Continuous Improvement: Establishing metrics and monitoring systems to ensure ongoing optimisation.

For instance, a process optimizer might introduce a new scheduling system that reduces machine idle time or implement quality control checkpoints that decrease defect rates.

The role requires a blend of technical knowledge, analytical skills, and communication abilities to drive meaningful change.

Leveraging Technology for Process Optimization

Technology is a powerful enabler of process optimization in industrial operations. Modern tools can automate data collection, provide real-time insights, and facilitate decision-making.

Key technologies include:

Industrial Internet of Things (IIoT): Sensors and devices connected to the internet that monitor equipment health and performance.

Data Analytics Platforms: Software that analyses large datasets to identify trends and anomalies.

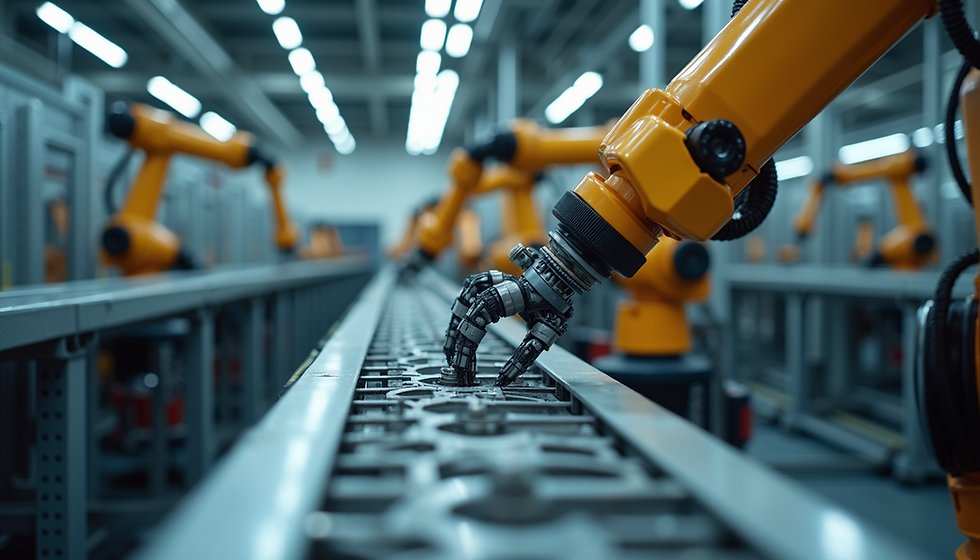

Automation Systems: Robotics and control systems that perform repetitive tasks with precision.

Enterprise Resource Planning (ERP): Integrated software that manages business processes across departments.

By integrating these technologies, companies can achieve higher accuracy, faster response times, and better resource management.

For businesses looking to enhance their operations, partnering with experts offering process optimization services can provide tailored solutions that fit specific needs.

Best Practices for Sustaining Streamlined Operations

Streamlining industrial operations is not a one-time effort but an ongoing process. To maintain efficiency gains, consider these best practices:

Regular Training: Keep employees updated on new tools and procedures.

Performance Metrics: Establish KPIs to measure productivity, quality, and safety.

Feedback Mechanisms: Encourage workers to report issues and suggest improvements.

Preventive Maintenance: Schedule routine checks to avoid unexpected equipment failures.

Lean Principles: Adopt lean manufacturing techniques to eliminate waste continuously.

By embedding these practices into the company culture, organisations can ensure that process optimization delivers long-term benefits.

Streamlining industrial operations through process optimization is a strategic approach that drives efficiency, reduces costs, and enhances competitiveness. By mapping processes, leveraging technology, and fostering continuous improvement, industries can adapt to evolving demands and achieve sustainable growth.

Comments