Reducing Energy Waste in Industrial Operations

- Aug 8, 2025

- 3 min read

Industrial operations consume vast amounts of energy daily. Inefficient energy use not only increases operational costs but also contributes to environmental degradation. Reducing energy waste is essential for improving profitability and sustainability. One of the most effective ways to achieve this is through energy monitoring, which provides detailed insights into energy consumption patterns and helps identify areas for improvement.

The Importance of Energy Monitoring in Industrial Settings

Energy monitoring is the process of tracking and analysing energy use within an industrial facility. It involves collecting data from various equipment and systems to understand how energy is consumed. This information is crucial for making informed decisions about energy management.

By implementing energy monitoring, industries can:

Detect energy wastage in real-time

Identify inefficient machinery or processes

Schedule maintenance to prevent energy losses

Optimise production schedules to reduce peak energy use

Track progress towards energy reduction goals

For example, a manufacturing plant might discover that certain machines consume excessive energy during idle times. By adjusting operational schedules or upgrading equipment, the plant can significantly reduce energy waste.

How Energy Monitoring Systems Help Cut Energy Waste

Modern energy monitoring systems use sensors and software to provide continuous feedback on energy consumption. These systems can be integrated with existing industrial infrastructure to offer detailed analytics and alerts.

Key features of effective energy monitoring systems include:

Real-time data collection - Immediate visibility into energy use allows quick response to anomalies.

Historical data analysis - Identifies trends and recurring issues over time.

Automated reporting - Simplifies compliance with energy regulations and internal targets.

Customisable alerts - Notifies managers of unusual energy spikes or equipment failures.

One practical example is the use of variable frequency drives (VFDs) controlled by energy monitoring data. VFDs adjust motor speeds based on demand, reducing unnecessary energy consumption.

Additionally, industrial energy monitoring systems can be tailored to specific industries, ensuring that the unique energy profiles of different operations are accurately captured and optimised.

Strategies for Reducing Energy Waste in Industrial Operations

Reducing energy waste requires a combination of technology, process improvements, and employee engagement. Here are some actionable strategies:

1. Conduct Energy Audits

Regular energy audits help identify inefficiencies and areas for improvement. Audits involve inspecting equipment, reviewing energy bills, and analysing operational practices.

2. Upgrade to Energy-Efficient Equipment

Replacing outdated machinery with energy-efficient models can lead to substantial savings. Look for equipment with high energy ratings and smart controls.

3. Implement Preventive Maintenance

Well-maintained equipment operates more efficiently. Scheduled maintenance prevents leaks, friction losses, and other issues that increase energy use.

4. Optimise Lighting and HVAC Systems

Industrial lighting and heating, ventilation, and air conditioning (HVAC) systems often consume large amounts of energy. Switching to LED lighting and using programmable thermostats can reduce waste.

5. Train Employees on Energy Conservation

Educating staff about energy-saving practices encourages responsible behaviour. Simple actions like turning off unused equipment can add up.

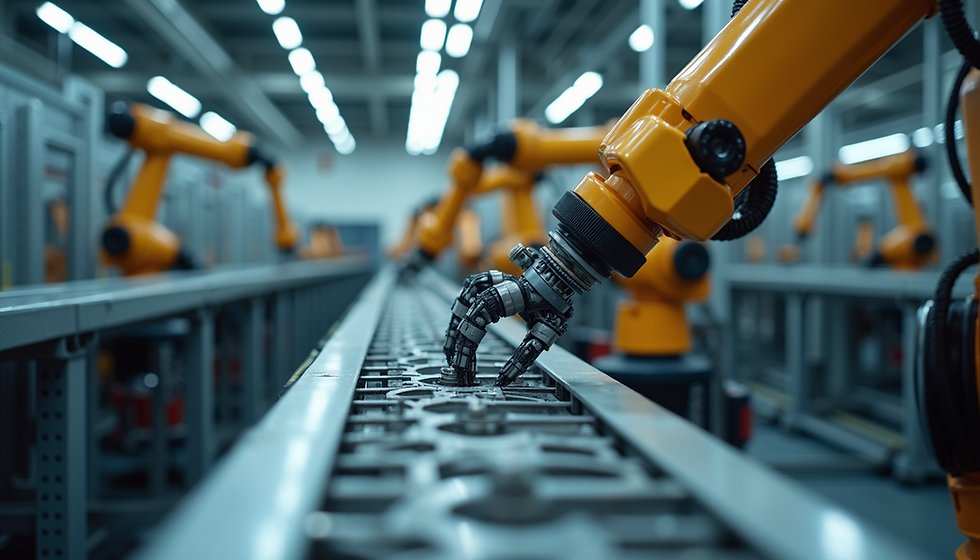

6. Use Automation and Control Systems

Automated systems can adjust energy use based on real-time demand, reducing unnecessary consumption during low production periods.

7. Monitor and Analyse Energy Data Continuously

Continuous monitoring allows for ongoing optimisation. Use data to set benchmarks and track improvements.

Leveraging Technology for Sustainable Industrial Energy Use

Technology plays a pivotal role in reducing energy waste. Innovations such as IoT sensors, AI-driven analytics, and cloud computing enable smarter energy management.

IoT Sensors: Collect granular data from machines and processes.

AI Analytics: Predict energy consumption patterns and recommend optimisations.

Cloud Platforms: Provide accessible dashboards for remote monitoring and collaboration.

By integrating these technologies, industries can move from reactive to proactive energy management, anticipating issues before they cause waste.

Moving Towards a Greener Industrial Future

Reducing energy waste is not just about cutting costs; it is also about corporate responsibility and environmental stewardship. Industries that prioritise energy efficiency contribute to lower carbon emissions and help combat climate change.

Adopting energy monitoring and waste reduction strategies can improve competitiveness by:

Lowering operational expenses

Enhancing brand reputation

Meeting regulatory requirements

Attracting environmentally conscious customers and partners

The journey to energy efficiency is ongoing. Continuous improvement, supported by data-driven insights, will ensure that industrial operations remain sustainable and profitable.

By embracing energy monitoring and implementing practical waste reduction measures, industrial facilities can achieve significant energy savings. The integration of industrial energy monitoring systems is a critical step towards smarter, greener, and more efficient operations.

Comments