Key Benefits of Streamlined Industrial Processes

- Jun 6, 2025

- 4 min read

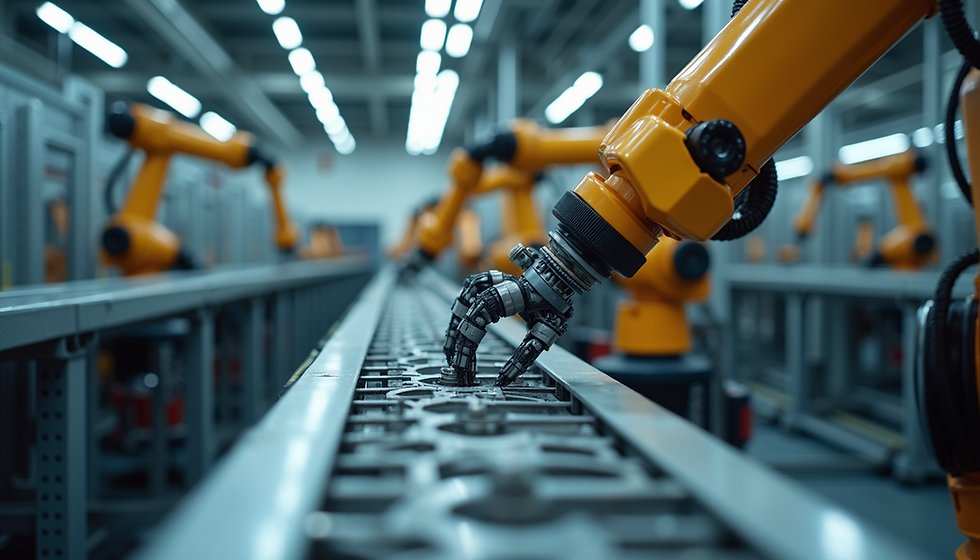

In today's fast-paced industrial landscape, companies are constantly searching for ways to improve efficiency and reduce costs. Streamlined industrial processes stand at the forefront of this endeavor, offering a myriad of benefits that can position a business for success. By adopting strategies that promote efficiency, businesses can enhance productivity, minimize waste, and improve overall operational effectiveness.

Understanding Streamlined Processes

Streamlined processes involve the simplification and optimization of workflows, eliminating unnecessary steps while enhancing job functions. This approach focuses on creating smoother, faster, and more efficient operations. Implementing these streamlined processes often results in greater consistency, higher-quality outputs, and improved employee satisfaction. Companies that effectively streamline operations tend to stay ahead of their competition, responding swiftly to market demands and changes.

One notable example of streamlined processes can be seen in the manufacturing sector. Companies that implement Lean principles report a marked reduction in cycle times and inventory costs. According to a recent study, organizations that undertook Lean transformations experienced an average productivity increase of 30%. This demonstrates how simple adjustments to workflows can yield significant outcomes.

Enhanced Operational Efficiency

One of the most significant advantages of streamlined industrial processes is enhanced operational efficiency. When companies focus on reducing unnecessary steps in their workflows, they can accomplish tasks more quickly and with fewer resources. This efficiency is particularly beneficial in high-volume environments where time and precision are critical.

For instance, a car manufacturing plant that streamlined its assembly line saw a dramatic reduction in the time taken to produce each vehicle. They eliminated redundant tasks and optimized the layout of their production floor, allowing workers to execute their responsibilities with greater speed and accuracy.

By adopting techniques such as Just-In-Time (JIT), companies can keep inventory levels low while ensuring that materials arrive precisely when needed. This reduces storage costs, minimizes waste, and enhances the overall value chain.

Increased Quality Control

Streamlined processes also contribute to improved quality control. By minimizing complexity in workflows, businesses can establish more consistent practices, leading to a reduction in errors.

Take the food processing industry as an example. By implementing standardized operating procedures and streamlined workflows, companies ensure that every product meets the utmost safety and quality standards. This commitment not only helps avoid costly recalls but also fosters consumer trust.

Implemented correctly, quality management systems can lead to increased customer satisfaction and retention, resulting in long-term business success. A focus on quality also positions companies as leaders in their fields, inviting new partnerships and clientele.

Cost Reductions

Another tangible benefit of streamlined industrial processes is cost reductions. By improving efficiency and quality, businesses can significantly decrease operational costs. This is accomplished in several ways:

Labor Savings: Streamlined processes often lead to less time spent on work, allowing businesses to complete tasks with fewer employees or engage staff in higher-value activities.

Lower Material Costs: Improved efficiency often correlates with reduced waste, as materials are used more effectively.

Reduced Downtime: Optimizing processes decreases the likelihood of errors and equipment failures, directly impacting production schedules and costs.

For instance, organizations that adopt industrial automation solutions can experience a significant reduction in labor costs while increasing output. As machines take over repetitive tasks, employees can focus on more complex challenges that contribute greater value to the organization.

Enhanced Employee Satisfaction

Streamlined industrial processes not only benefit the business but also improve employee satisfaction. By removing redundancies and simplifying workflows, employees experience less frustration in their roles. This sense of clarity and purpose often translates into higher morale and productivity levels.

Moreover, with efficient processes, employees can manage their time better, leading to a healthier work-life balance. Companies that prioritize streamlined operations often witness lower turnover rates as employees feel valued and supported in their work environment.

Organizations can also enable workers to participate in the process improvement initiatives, fostering a culture of innovation. When employees have a say in how processes are optimized, their commitment to the organization increases, translating into higher retention rates and productivity.

Strategic Business Growth

The implementing of streamlined industrial processes can ultimately lead to strategic business growth. By achieving efficiency, quality, and cost-effectiveness, businesses are better positioned to take on new opportunities, adapt to changes in the market, and meet customer demands.

For instance, a logistics company that streamlined its delivery processes not only reduced costs but was also able to expand effectively into new markets. The time taken to deliver goods was significantly reduced, allowing the company to compete on speed, a critical factor in customer satisfaction.

In conclusion, organizations must recognize that investing in streamlined industrial processes is essential for sustained success. The integration of advanced methodologies and technologies enhances productivity while minimizing waste and costs. Businesses that embrace this philosophy will not only improve their internal operations but also create a competitive edge within their industry.

Deciding to prioritize streamlined processes can lead to a transformational change, enabling businesses to thrive in today’s demanding marketplace. Companies that take the next step by exploring industrial automation solutions will find themselves well-equipped in the journey toward operational excellence.

Comments