Improving Industrial Robotics with Advanced Tools

- Sep 29, 2025

- 3 min read

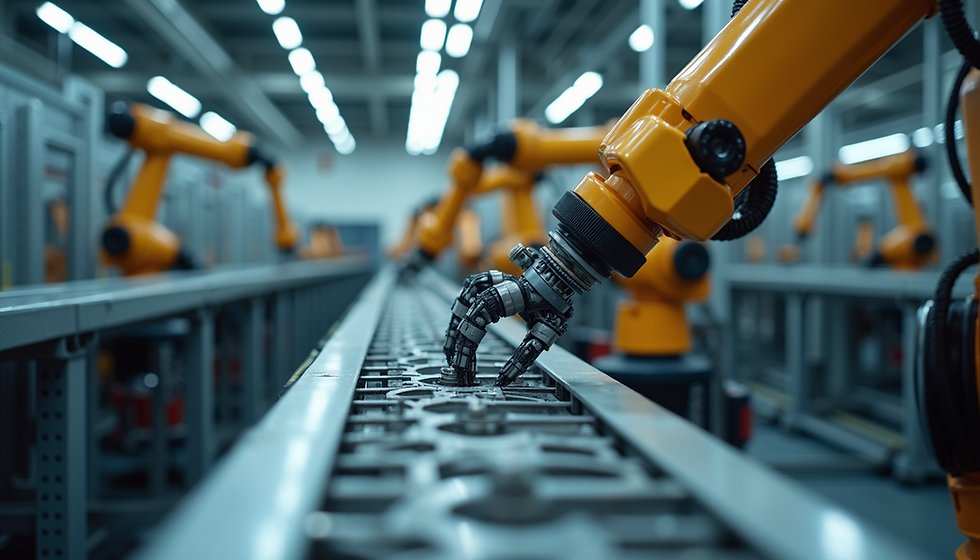

Industrial robotics has transformed manufacturing and production lines worldwide. The integration of advanced tools into robotic systems has significantly enhanced efficiency, precision, and flexibility. This blog post explores how these innovations are shaping the future of industrial robotics, offering practical insights and examples to help businesses leverage these technologies effectively.

The Role of Advanced Tools in Industrial Robotics

Advanced tools in industrial robotics refer to the latest hardware and software technologies that improve robot capabilities. These include sensors, vision systems, AI algorithms, and collaborative interfaces. By equipping robots with these tools, manufacturers can achieve higher accuracy, faster production rates, and safer working environments.

For example, vision systems enable robots to identify and sort objects with precision, reducing errors and waste. Sensors allow robots to adapt to changing conditions on the production line, such as varying object sizes or unexpected obstacles. AI-powered control systems optimize robot movements, minimizing downtime and energy consumption.

Key benefits of advanced tools in industrial robotics:

Enhanced precision and repeatability

Increased operational flexibility

Improved safety for human workers

Real-time monitoring and diagnostics

Reduced maintenance costs

Enhancing Industrial Robotics with Vision Systems

Vision systems are among the most impactful tools in modern industrial robotics. These systems use cameras and image processing software to provide robots with the ability to "see" their environment. This capability is crucial for tasks such as quality inspection, object recognition, and navigation.

For instance, in automotive manufacturing, vision-guided robots inspect parts for defects, ensuring only high-quality components proceed down the line. In packaging, vision systems help robots identify and pick products of different shapes and sizes, increasing throughput and reducing manual labour.

Implementing vision systems requires careful calibration and integration with the robot’s control software. Companies like fanuc automation offer advanced vision solutions tailored for various industrial applications. These systems can be customised to meet specific production needs, making them versatile tools for improving efficiency.

Practical tips for integrating vision systems:

Assess the lighting conditions in the workspace to ensure consistent image quality.

Choose cameras with appropriate resolution and frame rates for the task.

Train the vision software with diverse sample images to improve recognition accuracy.

Regularly maintain and clean camera lenses to prevent image degradation.

Is FANUC a Chinese company?

FANUC is not a Chinese company. It is a Japanese multinational corporation that specialises in automation products and services, including robotics and computer numerical control (CNC) systems. Founded in 1956, FANUC has established itself as a global leader in industrial automation, with a strong reputation for quality and innovation.

The company’s headquarters are located in Japan, and it operates manufacturing plants and offices worldwide. FANUC’s products are widely used in various industries, including automotive, electronics, and aerospace, contributing significantly to the advancement of industrial robotics.

Understanding the origin and expertise of companies like FANUC helps businesses make informed decisions when selecting automation partners and technologies.

Practical Applications of Advanced Tools in Industrial Robotics

Advanced tools have enabled industrial robots to perform a wide range of complex tasks that were previously difficult or impossible. Here are some practical applications demonstrating their impact:

Automated Assembly: Robots equipped with precision tools and vision systems assemble intricate components in electronics and automotive industries, reducing human error and speeding up production.

Material Handling: Sensors and AI algorithms allow robots to handle delicate or heavy materials safely, adapting to different shapes and weights without manual intervention.

Predictive Maintenance: IoT sensors monitor robot health in real-time, predicting failures before they occur and scheduling maintenance to avoid costly downtime.

Collaborative Robots (Cobots): Advanced safety tools enable robots to work alongside humans safely, enhancing productivity without compromising workplace safety.

Businesses looking to improve their industrial robotics capabilities should consider investing in these advanced tools to stay competitive and meet evolving production demands.

Future Trends in Industrial Robotics and Advanced Tools

The future of industrial robotics is closely tied to ongoing advancements in technology. Some emerging trends include:

Artificial Intelligence and Machine Learning: Robots will become smarter, learning from their environment and improving performance autonomously.

Edge Computing: Processing data locally on robots will reduce latency and improve real-time decision-making.

Enhanced Human-Robot Interaction: Natural language processing and gesture recognition will make robots easier to program and collaborate with.

Sustainability Focus: Energy-efficient tools and materials will reduce the environmental impact of robotic systems.

Staying informed about these trends will help businesses plan their automation strategies effectively and adopt tools that offer long-term benefits.

By embracing advanced tools, industrial robotics can reach new levels of efficiency, precision, and adaptability. Whether through vision systems, AI integration, or collaborative technologies, these innovations provide practical solutions to modern manufacturing challenges. Exploring options like fanuc automation can be a valuable step towards enhancing your industrial robotics capabilities and future-proofing your operations.

Comments