How Automation Is Revolutionizing the Industry

- May 21, 2025

- 4 min read

Automation has changed the way industries operate. From manufacturing to logistics, technology continues to evolve, transforming processes that once relied on human input. The push for efficiency and enhanced performance has spurred the integration of automation technologies into everyday business practice. In this article, we will explore how industrial automation is revolutionizing various sectors and the profound impact it has on production, safety, and sustainability.

Understanding Industrial Automation

Industrial automation involves the use of control systems, such as computers and robots, to handle processes and machinery in an industry to replace human intervention. By implementing these systems, companies can streamline operations, reduce errors, and increase productivity. As industries adapt to fast-paced market changes, adopting automated solutions has become essential for maintaining competitiveness.

Automation technologies encompass a wide range of tools and solutions, including robotic process automation (RPA), smart sensors, and artificial intelligence (AI). These innovations have enabled businesses to not only improve their operational efficiency but also gather data for better decision-making processes.

Key Benefits of Industrial Automation

The benefits of industrial automation are numerous. Let’s delve deeper into some key advantages:

Increased Efficiency: Automated systems can work continuously without the need for breaks or downtime. They can perform repetitive tasks at a much faster rate than human workers, leading to higher output levels.

Enhanced Accuracy: Automation reduces the risk of human error. Machines can complete tasks with precision, ensuring high-quality products and reducing waste in manufacturing processes.

Cost Savings: Though the initial investment in automation technology may be significant, companies can save money in the long run. Automation allows businesses to reduce labor costs and operational expenses, thus leading to higher profit margins.

Improved Safety: Automated systems can handle dangerous tasks, minimizing the risk of workplace accidents. For instance, in hazardous environments like chemical plants, robots can perform tasks that would be unsafe for human workers.

Increased Production Flexibility: Automation allows companies to adapt their processes quickly in response to changes in demand. Flexible manufacturing systems can be reprogrammed to produce different products with minimal downtime.

What is an example of advanced process control?

Advanced process control (APC) is a category of control systems that leverage sophisticated algorithms to optimize production processes. One prominent example of APC is the control of temperature and pressure in chemical reactors. A chemical plant might use an APC system to ensure that the conditions are precisely maintained to maximize yield and minimize waste. This real-time adjustment leads to operational excellence by significantly enhancing precision compared to traditional control methods.

APC systems often combine feedback control and feedforward control strategies to manage processes effectively. They analyze incoming data and make predictions about future conditions to ensure that operations remain within specified parameters. Implementing such systems can result in various benefits, including reduced energy costs and increased product quality.

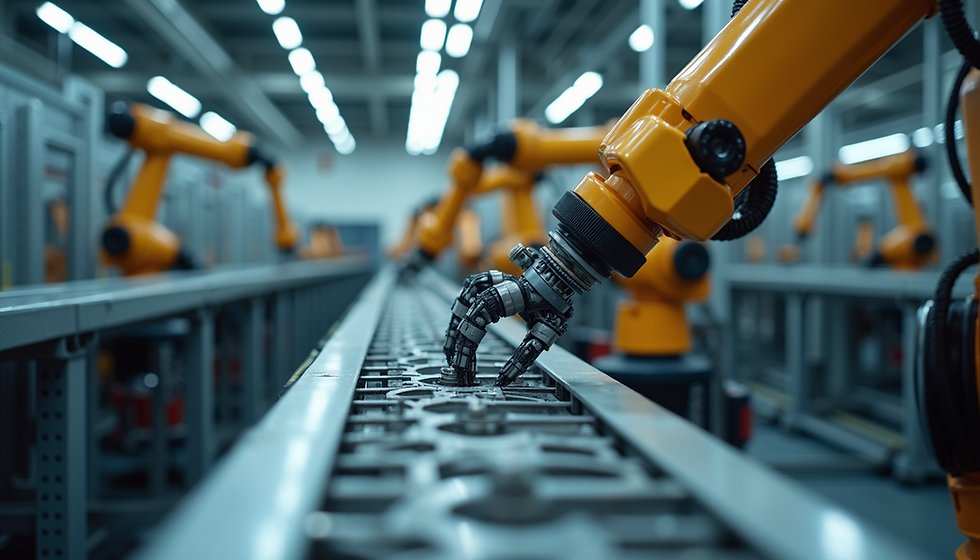

The Role of Robotics in Industrial Automation

Robotics play a pivotal role in the realm of industrial automation. Robotic systems can be programmed to perform a myriad of tasks, from assembling components to packaging finished products. These machines are equipped with sensors that enable them to detect and respond to their environment, ensuring greater accuracy and safety in operations.

In the automotive industry, for instance, robots have been integrated into assembly lines to streamline production processes. They can perform intricate tasks, such as welding and painting, with speed and precision. The implementation of robotics has led to shorter production cycles and improved product quality.

Statistics to Consider: According to the International Federation of Robotics, the global stock of operational industrial robots reached 3 million units in 2020, emphasizing the growing reliance on automation across sectors.

Challenges and Considerations of Automation

While automation offers significant advantages, it is essential to recognize the challenges that may arise during its implementation. Here are some considerations businesses should take into account:

High Initial Costs: The cost of integrating automation solutions can be substantial. Companies must evaluate the return on investment (ROI) to determine if automation is financially viable.

Job Displacement: As companies turn to automation, there is a risk of job losses for workers who are displaced by machines. Businesses should consider reskilling their workforce to ease the transition.

Technology Dependence: Over-reliance on automated systems may lead to vulnerabilities. It is vital to have contingency plans in place to manage system failures or cyber threats.

Maintenance and Upkeep: Automated systems require regular maintenance to function effectively. Companies must invest in training personnel to manage these systems and address technical issues promptly.

Future Trends in Industrial Automation

The future of industrial automation looks promising, with trends that are likely to define the next decade. Here are some key areas to watch:

Integration of AI and Machine Learning: AI technologies can analyze large datasets and improve decision-making processes in real-time. Companies that harness these capabilities can enhance operational efficiency and innovative solutions.

Edge Computing: By processing data closer to the source, edge computing reduces latency and supports real-time data analysis. This technology empowers companies to make quicker, informed decisions at various operational levels.

Sustainability through Automation: As industries face increasing pressure to adopt sustainable practices, automation can significantly reduce waste and energy consumption. Implementing energy-efficient systems can contribute positively to both the environment and the bottom line.

Collaborative Robots (Cobots): Unlike traditional industrial robots that operate independently, cobots work alongside human workers. This collaboration enhances productivity and enables staff to focus on higher-level tasks.

In summary, industrial automation is revolutionizing the industry. As companies leverage advanced control systems to optimize processes, they can achieve greater efficiency, accuracy, and safety. The future of automation is bright, marked by innovative technologies that will ensure companies remain competitive in today's rapidly changing market.

Embracing the Automation Revolution

To successfully navigate the changes brought by automation, businesses must consider their unique needs and challenges. As the technologies evolve, those willing to embrace this revolution can position themselves as leaders in their respective industries. The integration of automation can enhance operational efficiency and contribute to long-term growth and success. By making informed decisions and investing in the right technologies, companies can harness the power of automation to transform their operations for years to come.

Comments