Essential Services for Optimizing Industrial Operations

- Jun 17, 2025

- 3 min read

In today's fast-paced industrial environment, optimizing operations has become paramount for organizations to thrive. With the advent of new technologies and methodologies, there are specific services that can help businesses streamline their processes, improve efficiency, and ultimately enhance productivity. This blog post will delve into essential services that play a critical role in optimizing industrial operations, ranging from technology implementation to workforce training.

Understanding Industrial Services

Industrial services refer to a variety of support services provided to manufacturing and other industrial sectors, aimed at enhancing productivity and operational efficiency. These services encompass a wide range of functions, including equipment maintenance, operational consulting, and integration of technology solutions. For industries facing increased competition and rising operational costs, investing in effective industrial services is not just an option; it is a necessity.

An efficient industrial service can lead to a reduction in downtime, improved safety measures, and significant cost savings. For instance, companies that invest in preventive maintenance services often benefit from extended equipment life and reduced repair costs, reinforcing the importance of integrating industrial services into their operational strategy.

The Role of Technology in Enhancing Operations

Technology is a driving force behind modern industrial optimization. By adopting the latest advancements, organizations can achieve greater operational efficiency. Key technology-driven services include:

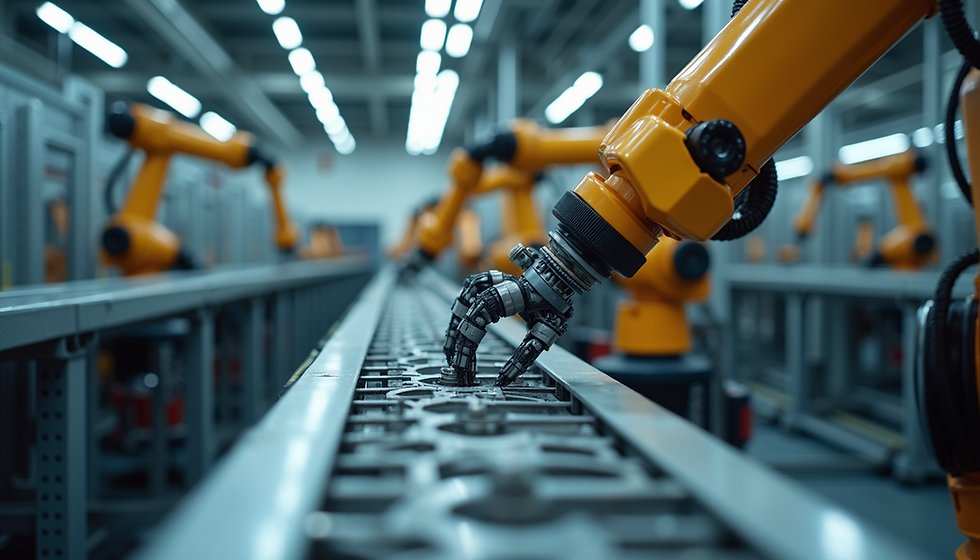

Automation Services: Implementing automation can significantly reduce manual labor, thereby minimizing human error and increasing speed. Automated systems for production lines and warehouse operations allow for seamless workflow and real-time monitoring.

Data Analytics: Harnessing data analytics tools can provide insights into operational performance, enabling managers to make informed decisions. By analyzing production data, organizations can identify bottlenecks and optimize processes accordingly.

Supply Chain Management Software: Using advanced supply chain management solutions helps companies track inventory levels, manage logistics, and streamline procurement processes. This leads to a reduction in lead times and improved customer satisfaction.

For industries seeking to incorporate these advancements, industrial automation services can be especially beneficial, as these services offer tailored solutions that align with specific operational needs.

Workforce Training and Development

Even with the best technology, the success of any industrial operation largely depends on its workforce. Continuous training and development are essential components of optimizing operations. Here are ways to invest in your team:

Skill Enhancement Programs: Providing employees with the necessary skills to operate new technologies ensures that operations run smoothly. Offering training sessions on equipment handling, safety protocols, and software utilization can drastically reduce errors and enhance productivity.

Lean Manufacturing Training: Teaching employees about lean principles helps minimize waste and improve the overall workflow. This approach can lead to significant cost reductions and a more effective production environment.

Safety Training: Implementing safety training is crucial for maintaining a secure workplace. It not only protects employees but also reduces liability costs for the organization. A safe environment fosters employee morale, contributing to higher productivity levels.

Investing in workforce development helps create a culture of continuous improvement, which is vital in maintaining operational excellence in the long term.

The Importance of Maintenance Services

Another crucial aspect of optimizing industrial operations is maintenance services. Proactive equipment maintenance can prevent significant disruptions. Here’s why maintenance services should be a priority:

Predictive Maintenance: Utilizing data from machinery can forecast when maintenance is required. By detecting issues before they escalate, companies can avoid unplanned downtimes.

Routine Inspections: Regular inspections help to identify areas that may need attention before they become problematic. Keeping machinery in optimal condition ensures continuous operation and prolongs equipment life.

Equipment Upgrades: Technology is constantly evolving, and so should your machinery. Investing in newer models or retrofitting existing equipment can lead to increased efficiency and better output quality.

Integrating a comprehensive maintenance strategy into your operations is essential to minimize disruptions and enhance overall productivity.

Final Thoughts on Optimization Services

Optimizing industrial operations is a multifaceted effort that requires a strategic approach. From leveraging technology to investing in workforce training and maintenance services, every aspect plays a role in achieving operational excellence.

In conclusion, organizations must adopt a holistic view of their operations, considering not just the technology and equipment but also the individuals who power these systems. By focusing on essential services for optimization, businesses can navigate the challenges of the evolving industrial landscape, ensuring sustainability and success.

Comments